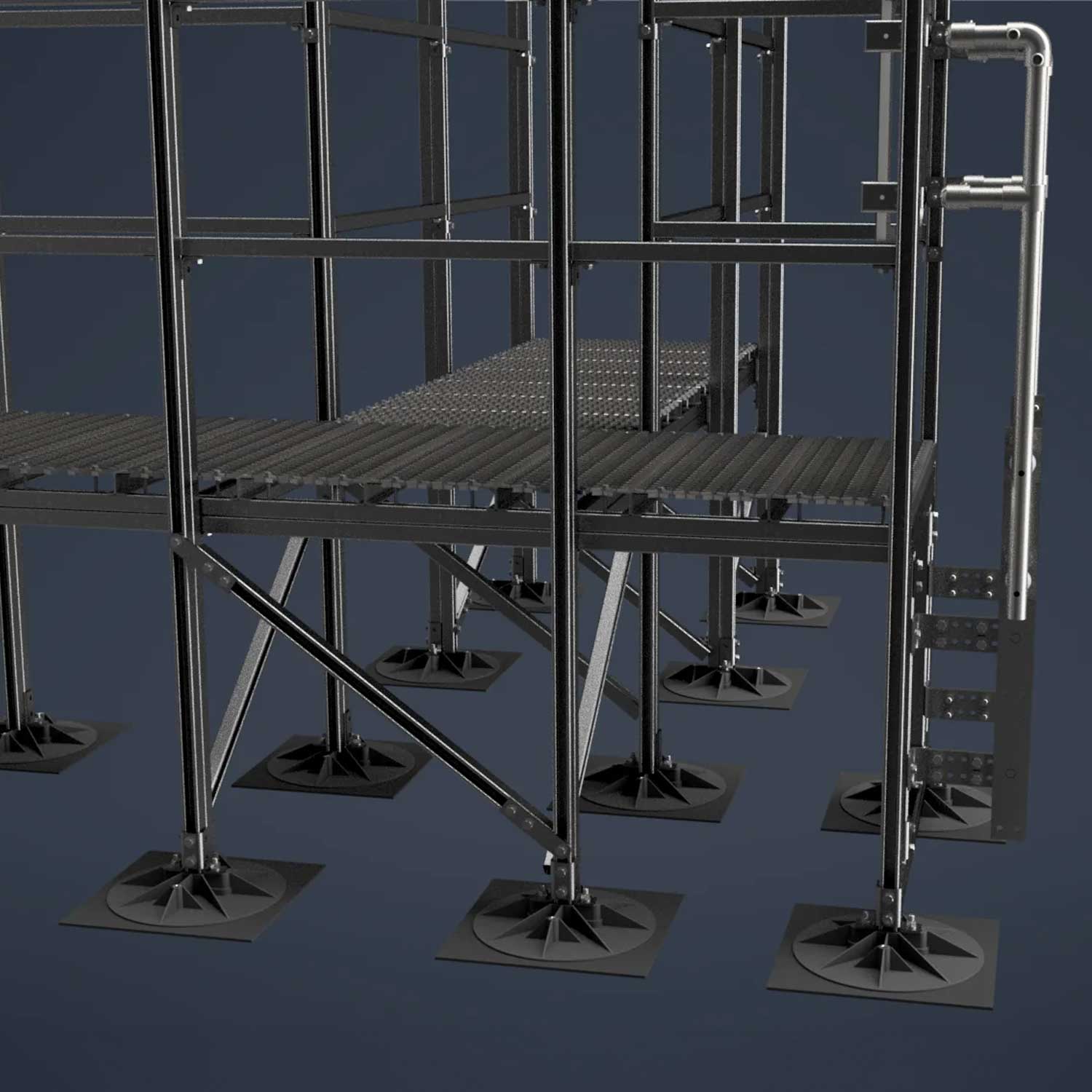

Polycarbonate Roof Support Base

Available as a stand-alone solution, our patented polycarbonate base has a versatile design that allows for many different uses and configurations.

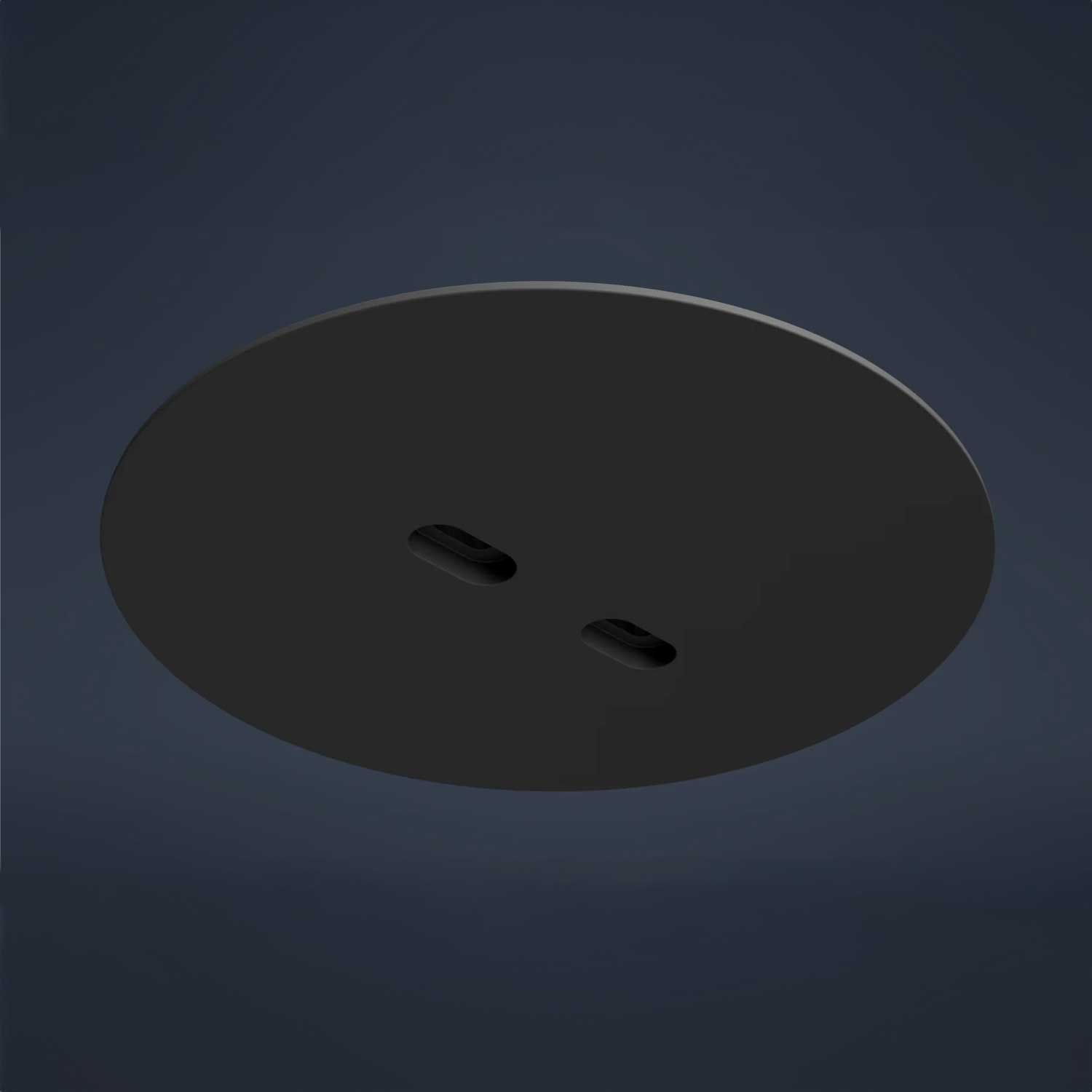

- 16" round base, allowing for any base orientation

- UV-stabilized polycarbonate material

- Threaded inserts integrated into base, or through-holes from the bottom to use bolts, allowing for many different attachment configurations

- High surface area on the solid bottom of the base allows for better distribution of load to roof membrane, keeping the PSI low and protecting the membrane and insulation.

Available from our partner Unistrut Service Company

Why is polycarbonate the best material choice for roof support bases?

Polycarbonate is a famously tough material. You may have heard about bulletproof plastic - those are thick clear polycarbonate sheets. Not only is it incredibly impact resistant, but with the right additives it can withstand the harsh elements found on a rooftop as well, allowing it to properly support rooftop equipment for years to come.

What about polypropylene bases?

There are manufacturers who make support bases out of polypropylene, a similar plastic to polycarbonate in many ways but with a few key differences. Both plastics are known for their durability, with excellent resistance to high temperatures and chemicals. Polypropylene is also relatively resistant to flex and impact. However, in all cases, specifically impact resistance, polycarbonate reigns supreme.

Due to its increased toughness and versatility, polycarbonate materials also cost more than polypropylene. However in a scenario such as rooftop support applications, the increased cost more than pays for itself over the life of the base, as it will be less prone to cracking and breaking, necessitating replacement.

Why is PSI important in roof support bases?

PSI is the measurement of force imparted from the weight of rooftop equipment down through the base and onto the surface of the roof. The lower the PSI the less force is exerted on the membrane, which increases its lifespan and protects the underlying insulation.

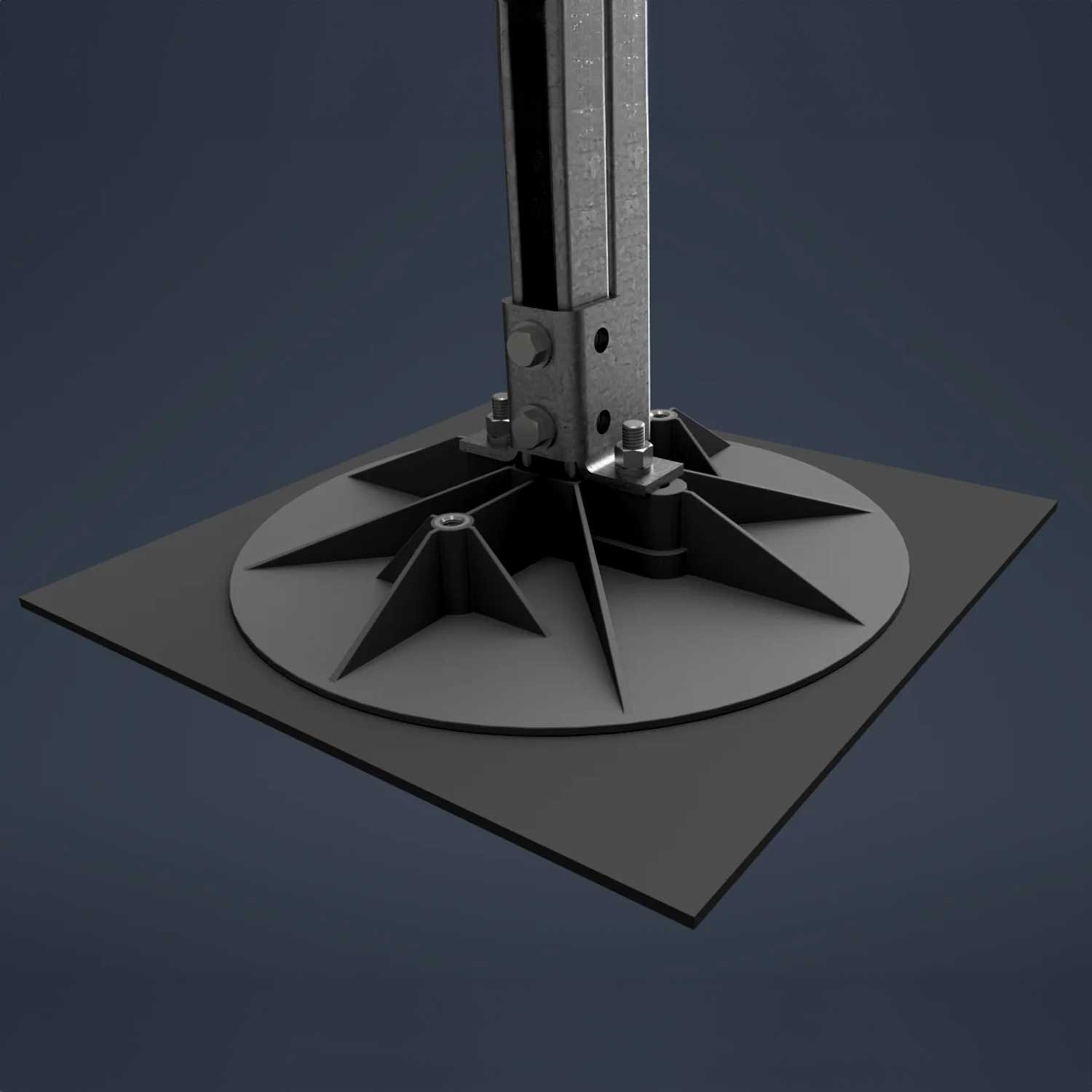

Generally speaking, the larger a roof support base, the lower the PSI will be since the load will be distributed over a larger surface area. However, some roof bases have hollow spaces on the underside of the base. Since that area is devoid of any material contacting the roof membrane, it reduces the effective surface area of the base, therefore increasing the PSI of the other parts of the base that do make contact with the roof.

A well-designed roof base will have maximum surface area on the bottom, allowing for larger loads without compromising the integrity of the roof. The underside of On Deck's polycarbonate base is almost entirely solid, allowing basically the entire base to distribute load to the roof.

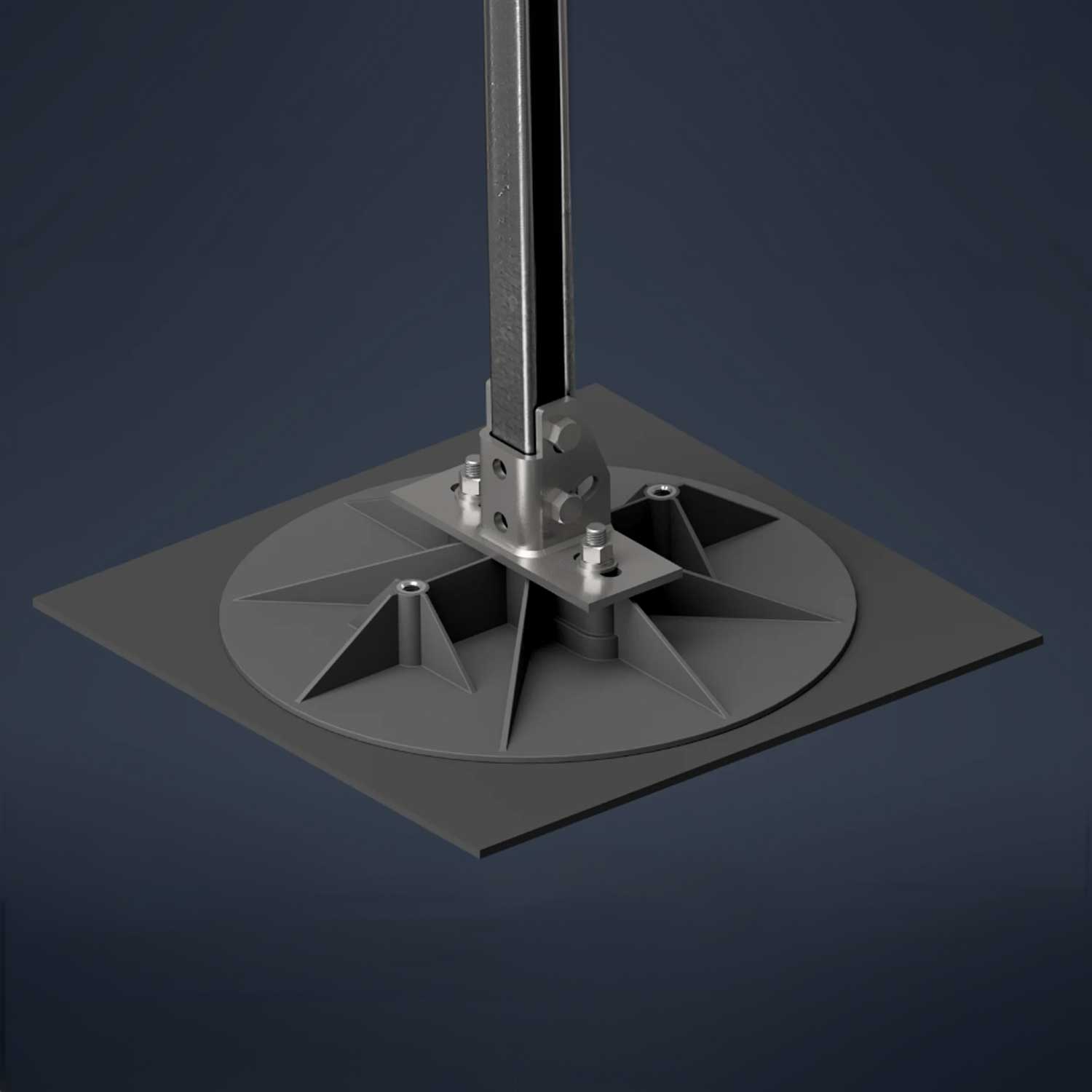

Is On Deck's base versatile?

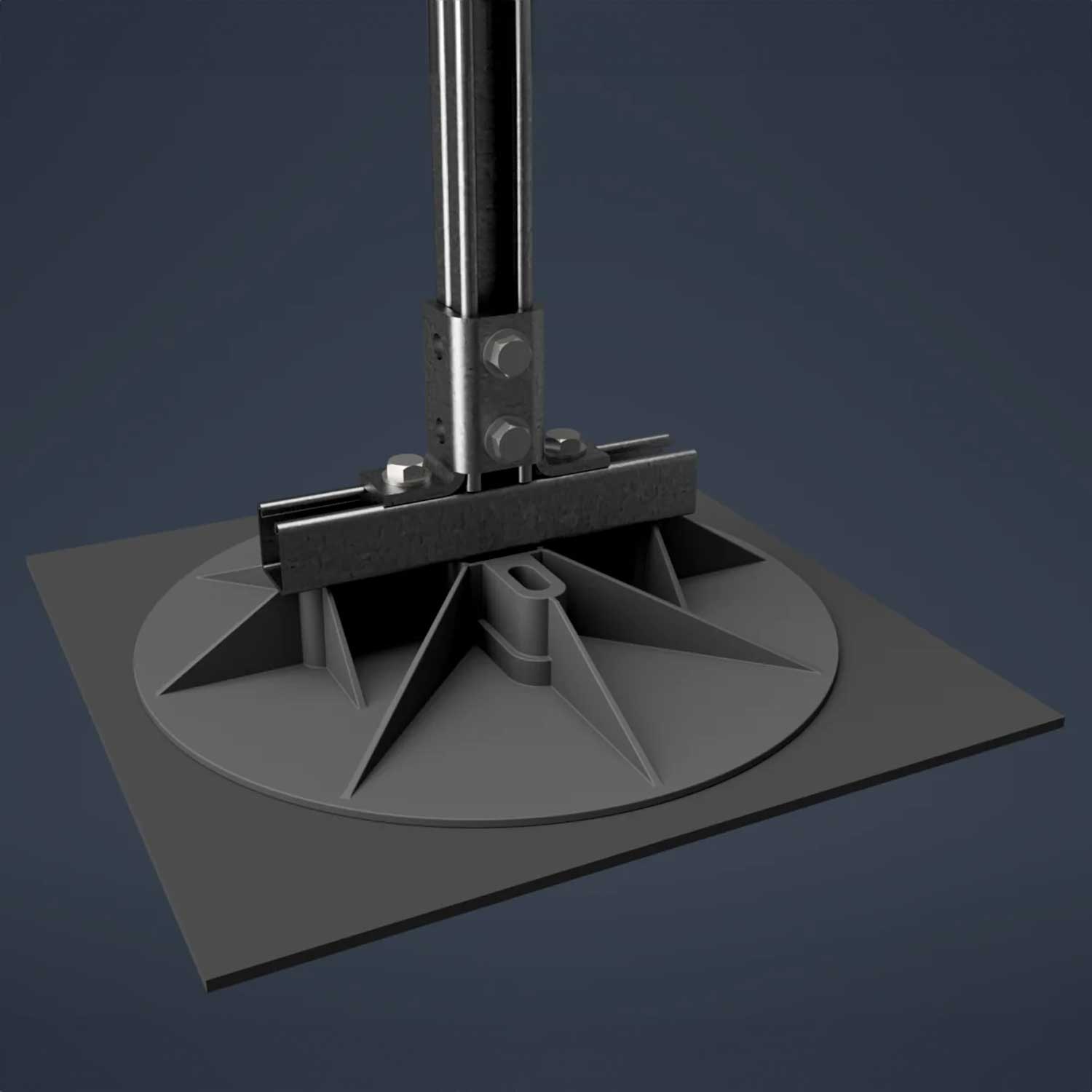

Absolutely. On Deck's base design allows for several different connection methods. It has threaded inserts, allowing material to be bolted directly into the base, as well as through-holes from the bottom, allowing bolts of the user's choice to be run from the bottom to the top of the base, where material can be fastened with washers and a nut.

Users may wish to attach a wing fitting to the base, or even a short length of channel. These options allow for broad applications and use-cases.